Visit Us

Products

Why Brands Choose MOZURU

Because we reduce the risk of your orders. Less rework. Less risk. Easier repeat orders.

We review your design files in advance and confirm all key specifications before sampling. This reduces unnecessary revisions and shortens the development cycle.

All specifications are locked after sample approval and reconfirmed before mass production. This ensures the final products match the approved sample exactly.

Quality checks are implemented at each production stage, not just at final inspection. Potential issues are identified early, minimizing quality disputes and after-sales risks.

We follow a structured production timeline and export-ready packing plan. This ensures stable delivery schedules and supports confident product launches and reorders.

Manufacturing Process

Factory Process (From raw materials to shipment-ready paddles

We don’t rely on one “final inspection.” We control quality at multiple stages:

-

Incoming material checks

-

In-process checkpoints(critical points that affect consistency)

-

Final inspection(appearance, construction, and batch consistency)

If your market requires stricter verification, we can also support third-party testing so your team can verify performance and compliance independently.

Material Selection

Choosing high-quality carbon fiber and fiberglass as the core materials for paddle strength and flexibility

CNC Routing

Precision-cutting the raw materials into the shape of paddles using CNC machines for consistent quality

Layering Process

Laminating the cut materials with resins to enhance durability and performance

Molding

Shaping the laminated materials into paddles through a heating process that uses molds for specific paddle designs

Cooling

Allowing the newly molded paddles to cool and set, ensuring they retain their shape and structural integrity

Edge Trimming

Cleaning up the edges of the paddles for a smooth finish and preparing them for additional components like edge guards

Surface Finishing

Applying surface treatments to improve the paddle's grip and aesthetics, such as UV printing for high-resolution graphics

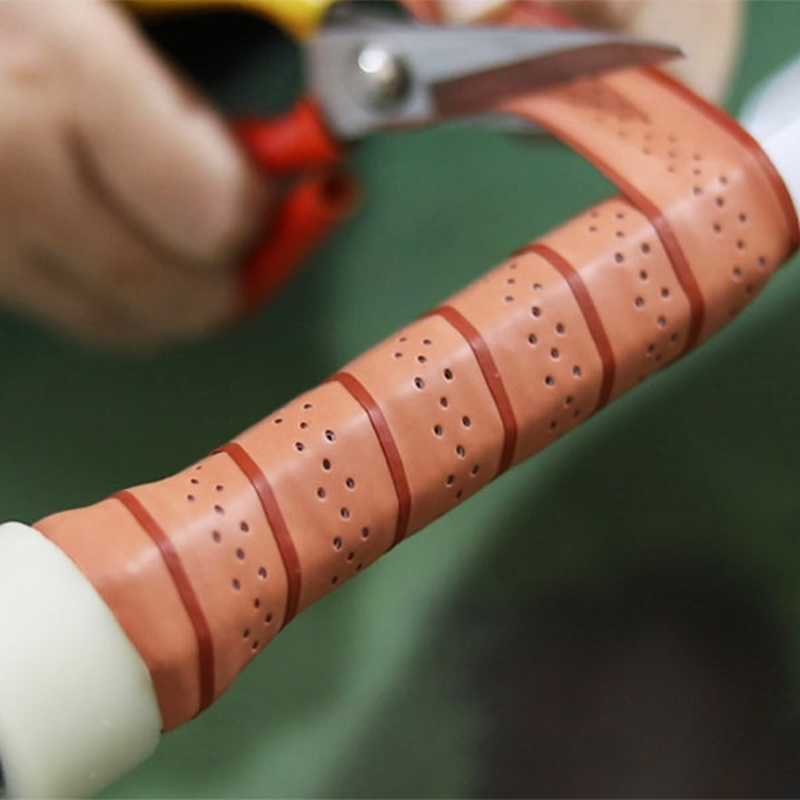

Handle Installation

Attaching the grip to the paddle, ensuring a comfortable and secure hold for players

Quality Inspection

Conducting thorough checks on each paddle for any manufacturing defects or inconsistencies